2006 B Potting

Product Details:

- Size Customized

- Usage Commercial

- Product Type Solder Paste

- Melting Point Normal

- Coating Polished

- Click to View more

2006 B Potting Price And Quantity

- 100 Pack

2006 B Potting Product Specifications

- Commercial

- Solder Paste

- Polished

- Customized

- Normal

2006 B Potting Trade Information

- Cash on Delivery (COD)

- 5000 Pack Per Month

- 10 Days

- All India

Product Description

Features & Benefits

- Low viscosity for good flowability.

- Low surface tension, Simple mix Ratio 1:1

- Good Thermal conductivity

Application

2006 A & B is designed to provide efficient heat transfer in electronic modules, including power supply. It is used in power electronic components, modular power supplies, circuit boards for potting application, LED drivers, automotive HID lamp power supply, automotive ignition system module power supply, network transformers, adaptors, inverters, transformers, sensors, electronics control units etc.

Mixing and de-airing

On Storage for few weeks, some sedimentation occurs, to ensure a uniform product mixing and performance the material in each container should be thoroughly mixed prior to use. Two-part material must be mixed in 1:1 ratio either by weight or volume. The presence of light-colored streaks or any color variation indicates inadequate mixing.

Useful Temperature Ranges

Operational over a temperature range of -45 to 150 Degree C for long periods of time. At high-temperature end, the durability of the cured silicone is mostly time and temperature dependent. Most of the times, the higher the temperature, the shorter the time the material will remain useable

Usable Life And Storage

The Product Should Be Stored In Its Original Packaging With The Cover Tightly Attached To Avoid Any Contamination. Store In Accordance With Any Special Instructions Listed On The Product Label.

Packing

- 25kg/Can

Specification

Property | Unit | Result |

One part or Two part |

| Two |

Color |

| Gray/White/ |

Mix Ratio |

| 1:1 |

Viscosity (Part A) | cP | 9500 app. |

Viscosity (Part B) | cP | 4200 app. |

Viscosity (Mixed) | cP | 6700 app. |

Specific Gravity- Cured |

| 2.20 |

Working Time at 25 Degree C | Hours | 6 |

Heat Cure at 120 Degree C | Minutes | 25 |

Durometer | Shore OO | 45 |

Penetration | 1/10 mm | 32 |

Elongation | % | 400 |

Tensile Strength | mPa | 4.3 |

Dielectric Strength | kV/mm | 18 |

Dielectric Constant | 100 Hz/ KHz | 4.6 |

Dissipation Factor | 100 Hz | 0.002 |

Volume Resistivity | Ohm-cm | 1.90E+14 |

Coefficient of Linear Thermal Expansion (CTE) | ppm/ Degree C | 175 |

Thermal Conductivity | W/mK | 0.80 |

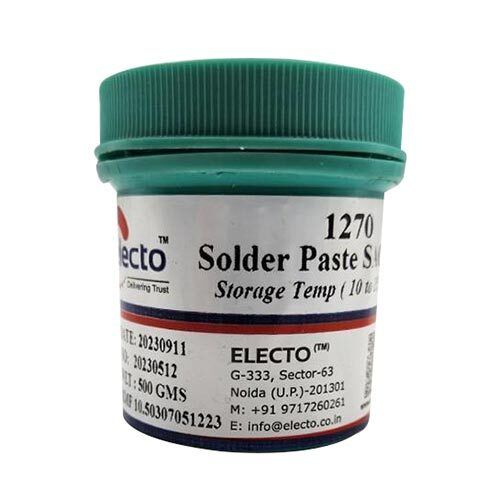

Other Products in 'Solder Paste' category

GST : 09AADCK2962R1ZT

Send Inquiry

Send Inquiry Send SMS

Send SMS